Pressure: 4.8MPa or higher

-

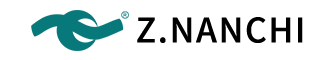

NG Standard Single Screw PumpCapacity: 0.1m³/h ~ 500m³/h

NG Standard Single Screw PumpCapacity: 0.1m³/h ~ 500m³/h

Pressure: 4.8MPa or higher

-

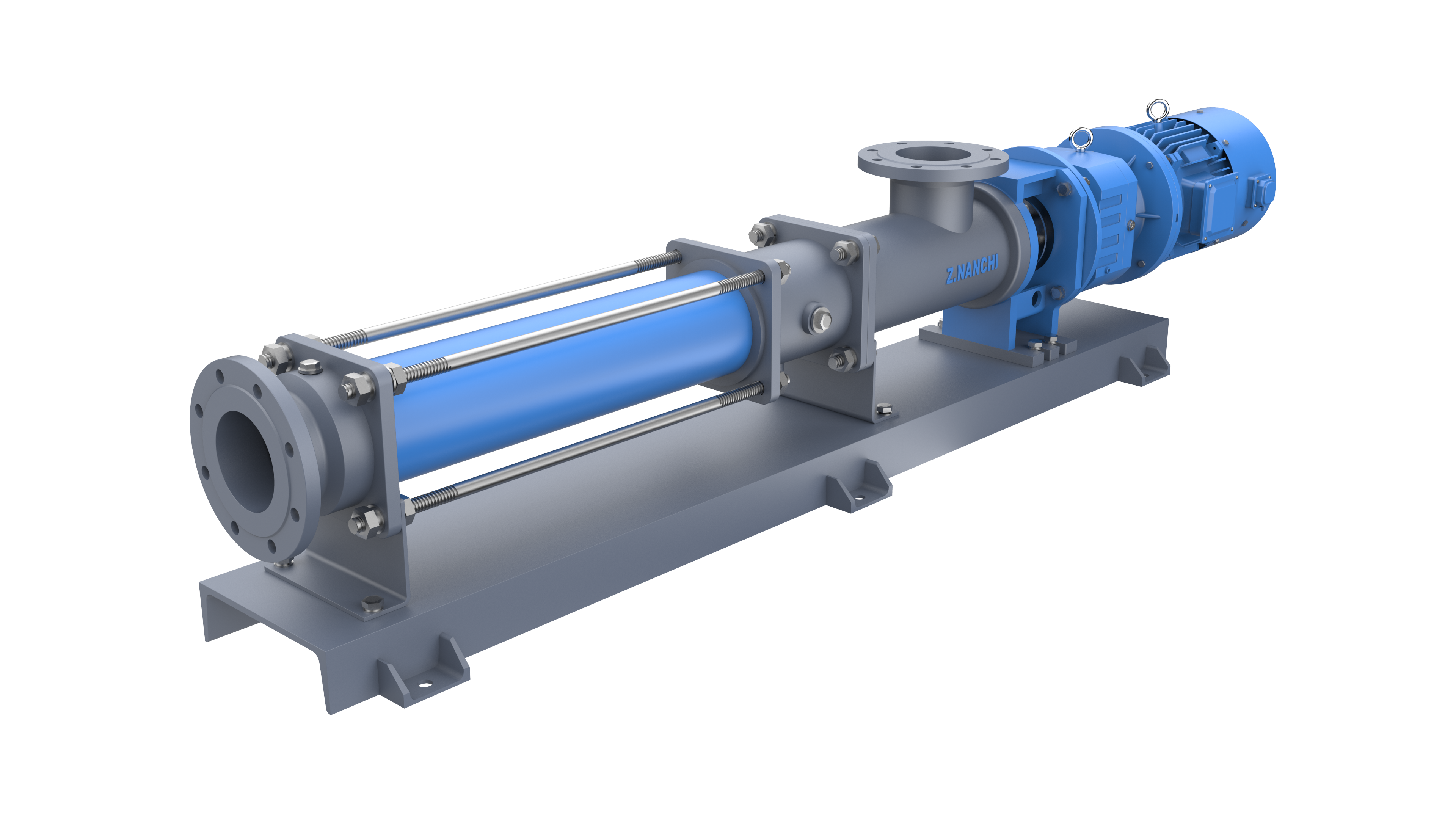

NS Mixing Feed PumpCapacity: 0.1m³/h ~ 400m³/h

NS Mixing Feed PumpCapacity: 0.1m³/h ~ 400m³/h

Pressure: 4.8MPa or higher

-

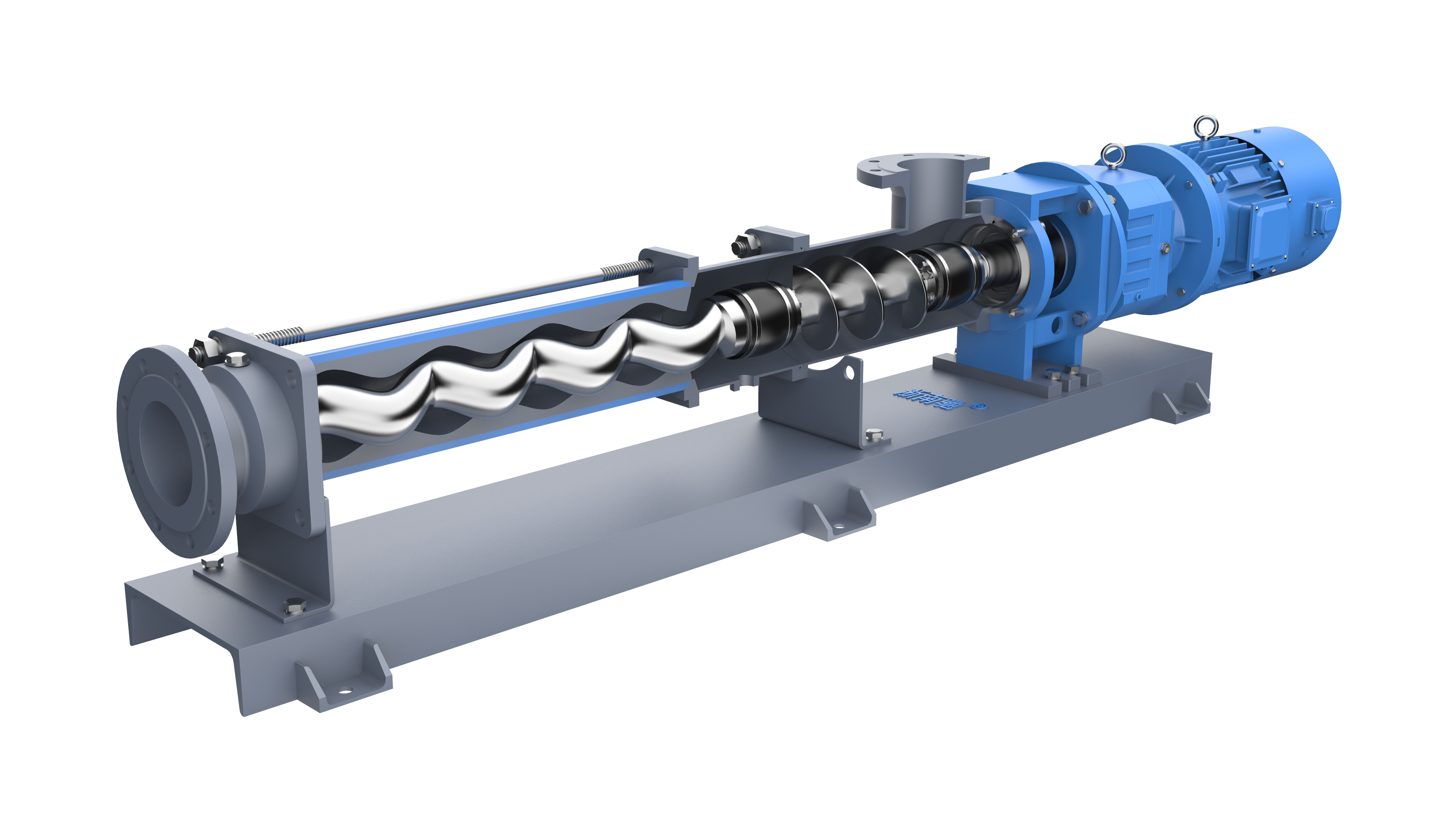

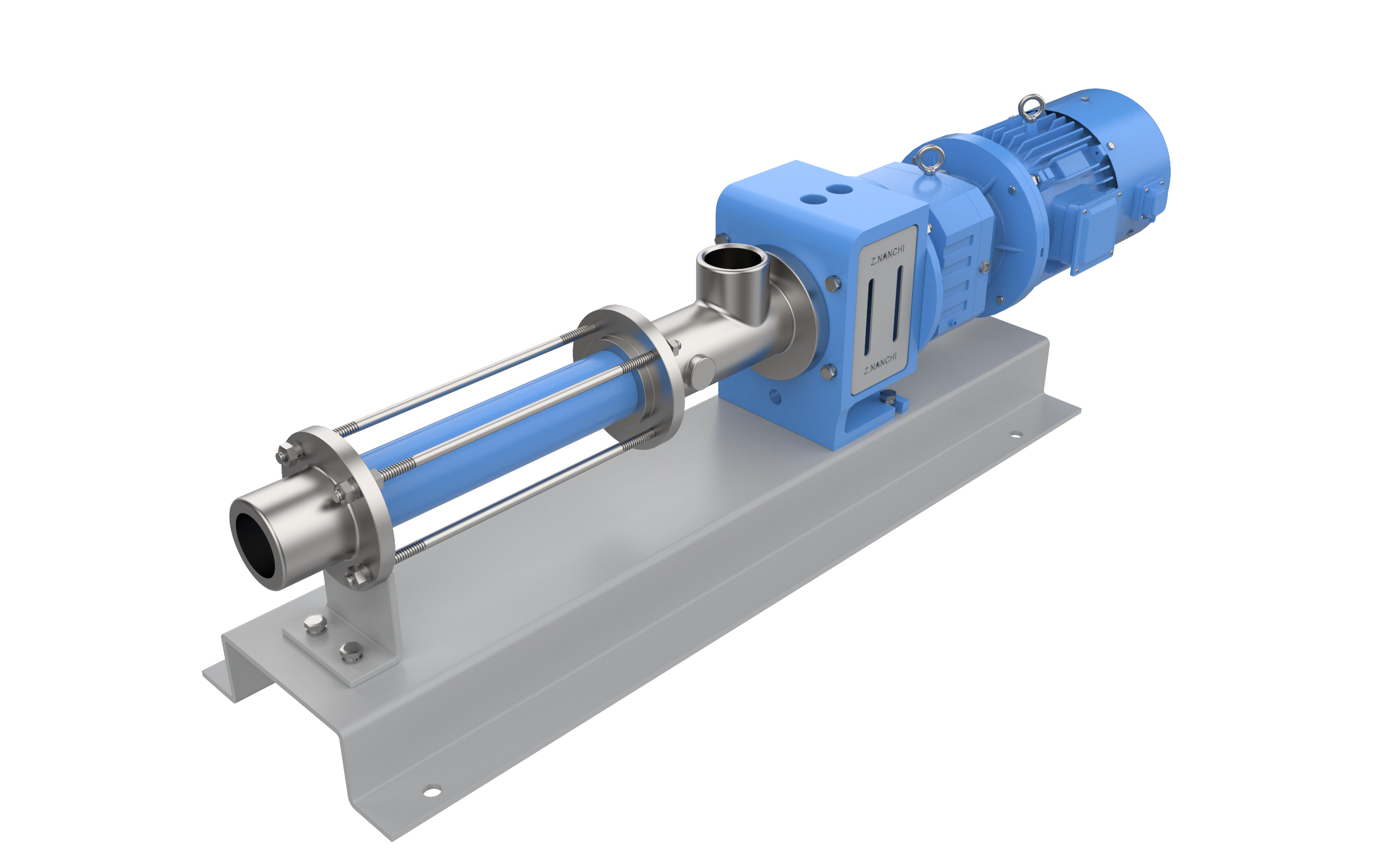

NH Food Hygienic PumpCapacity: 0.1m³/h ~ 200m³/h

NH Food Hygienic PumpCapacity: 0.1m³/h ~ 200m³/h

Pressure: 4.8MPa or higher

-

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

NP Metering PumpCapacity: 0.1L/h ~ 1000L/h

Pressure: 2.4MPa or higher

-

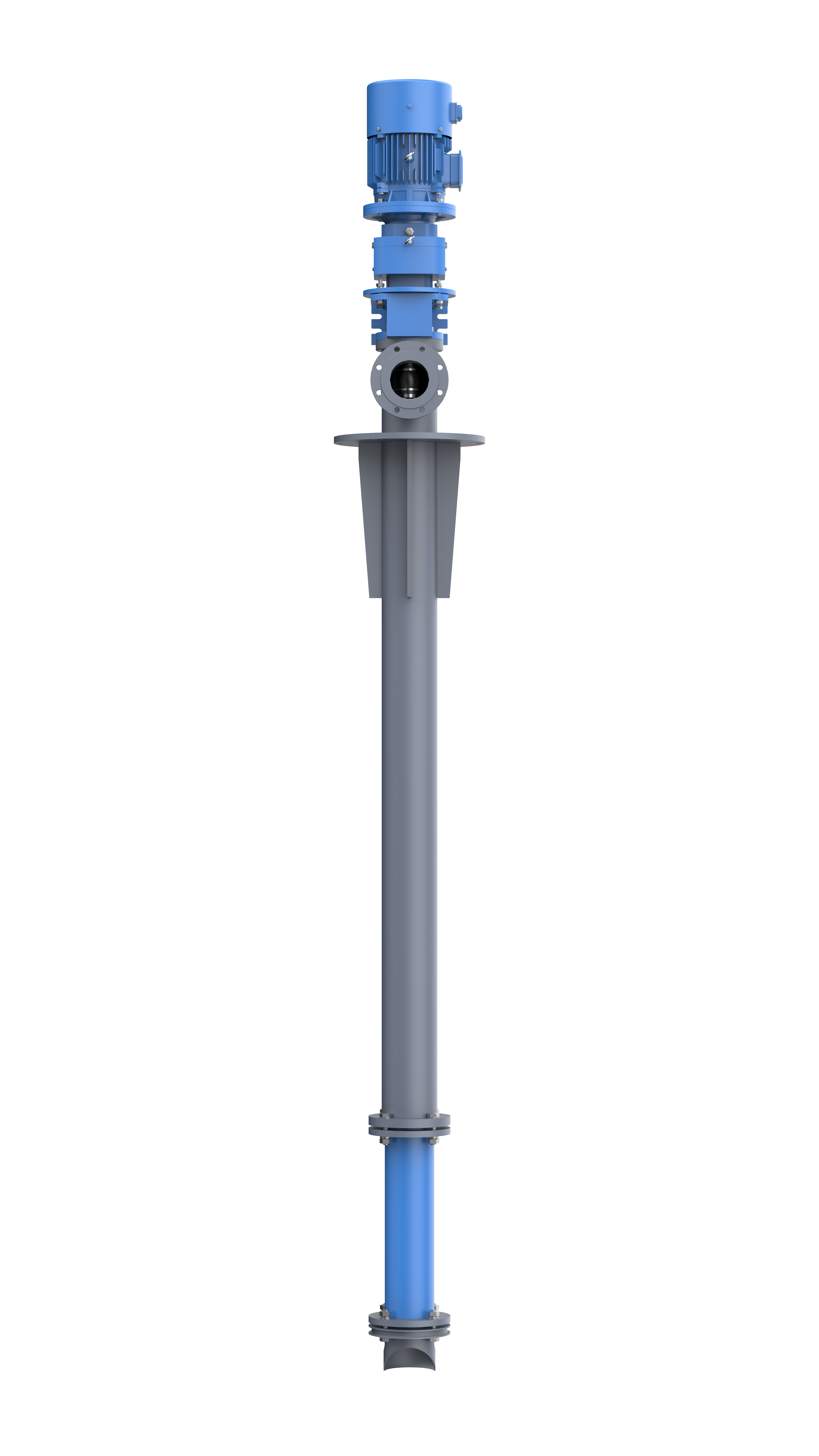

NV Vertical PumpCapacity: 0.1m³/h ~ 100m³/h

NV Vertical PumpCapacity: 0.1m³/h ~ 100m³/h

Pressure: 1.2MPa or higher

At present, oil refining methods widely used at home and abroad include self injection, rod pump, electric pump, hydraulic piston pump, screw pump and gas lift oil production. Chinese machinery manufacturing methods include rod pumps, electric submersible pumps and hydraulic piston pumps. Various methods of oil production have reasonable technical and economic limitations. These limitations depend not only on how well the method itself works, the equipment and technology used, but also on the geological characteristics of the reservoir, development policies and current development conditions. There are also many factors, such as environmental conditions. Therefore, it is important to optimize oil recovery methods at all stages of production, depending on reservoir conditions.

With the increase in the number of oil Wells containing heavy oil, sand and natural gas in various countries, oil recovery has become one of the main mechanical lift methods today. The production of oil has the advantages of less investment, simple equipment structure, convenient operation, energy saving, electricity saving, strong adaptability, and so on, which has attracted wide attention from domestic and foreign oil fields. Since 1990, Dasheng Oilfield has been using it to produce oil in a variety of well conditions, such as surrounding low-permeability fields, grouting adjusted well patterns in old urban areas, and polymer flooding tertiary production test areas. It is used in about 3,000 Wells. Oil recovery is not only suitable for high viscosity, high sand content, high oil/gas ratio reservoir development, but also suitable for late high water cut water Wells and polymer flooding of tertiary oil recovery. The practice shows that the production well also has high adaptability.

With the adoption of many new materials and new technology, as well as the development and progress of application technology, pumping technology has been continuously improved and significantly improved. Although significant progress has been made in service life, pump efficiency, reliability and economy, the adaptability of the single screw pump in developing various types of oil depots has been significantly improved, and its scope and foundation have been further expanded. Other methods of artificial lift have been covered. The technology is brand new. Compared with other mechanical pumping units, the single screw pump has the following advantages:

1. Save investment vertical screw pump, submersible electric pump, hydraulic piston pump and beam type (chain type) pump unit due to simple structure and relatively cheap.

2. The surface device is simple in structure and easy to install. It can be installed directly on the wellhead casing spool. The area occupied will be smaller. Apart from the original wellhead, it is a small percentage. Anti-theft wellhead room can be easily covered.

3 pump high efficiency, energy saving, low management cost. Because it is a positive displacement pump, the flow does not pulsate, the axial flow is continuous, and the flow is stable. As a result, there is no fluid column or mechanical drive inertia loss compared to the beam pump unit. The volume ratio of the pump can reach 90%. This is one of the models with the lowest energy consumption and the highest efficiency among the existing mechanical oil absorbers.

4. Suitable for all kinds of viscosity, can lift heavy oil. Generally, it is suitable for a wide range of crude fluids with viscosity less than 8000 mPa/s (50°C), so most heavy oils can be used.

5. Adapt to high manhole. Theoretically speaking, screw pump can transport sand content of 80% mortar. Crude oil is produced in large amounts of sand and has good compatibility with high water cut Wells and polymer flood stage 3 Wells in the latter half of the waterflood method.

With the adoption of many new materials and new technology, as well as the development and progress of application technology, the single screw pump pumping technology has been continuously improved and significantly improved. Although significant progress has been made in service life, pump efficiency, reliability and economy, the adaptability of screw pumps in the development of various types of oil depots has been significantly improved, and their scope and foundation have been further expanded. Other artificial lift methods already covered in screw pump technology are brand new. Compared with other mechanical pumping units, screw pumps have the following advantages:

1. Save investment screw pump, submersible electric pump, hydraulic piston pump and beam (chain) pump units due to simple structure and relatively cheap.

2. The surface device is simple in structure and easy to install. It can be installed directly on the wellhead casing spool. The area occupied will be smaller. Apart from the original wellhead, it is a small percentage. Anti-theft wellhead room can be easily covered.

3 pump high efficiency, energy saving, low management cost. Because it is a positive displacement pump, the flow does not pulsate, the axial flow is continuous, and the flow is stable. As a result, there is no fluid column or mechanical drive inertia loss compared to the beam pump unit. The volume ratio of the pump can reach 90%. This is one of the lowest energy consumption and highest efficiency models of the existing mechanical oil press.

4. Suitable for all kinds of viscosity, can lift heavy oil. Generally, screw pumps are suitable for a wide range of crude fluids with viscosity less than 8000 mPa/s (50°C), so most heavy oils can be used.

5. Adapt to high manhole. In theory, vertical screw pump can transport sand content of 80% mortar. Crude oil has a high sediment content and can be produced normally when the maximum sediment content reaches 40% (excluding buried sand).

6. Adapt to high gas Wells. Screw pumps are not air-locked, suitable for mixed oil and gas transport, but the downhole pump inlet free gas occupies a certain pump capacity.

7. Applicable to cluster well groups and horizontal Wells in offshore oil fields. Designed for use in inclined vertical intervals, the unit's small footprint makes it suitable for offshore cluster and horizontal Wells.

8. Increase the back pressure of the wellhead. Under normal pumping conditions, the wellhead back pressure can be controlled above 1.5MPa, which is useful for collecting and transporting Wells in remote areas.

9. If the engine or motor stops running, sand may stick to the top of the pump. More likely to return to work than a rod pump.

Since the introduction of pumping technology in Dacheng oilfield, its application scale has been expanding year by year, and it has rapidly developed into a general artificial pumping method. Various methods of oil production have reasonable technical and economic limitations. These constraints depend not only on how well the method works, the equipment and technology used, but also on the geological characteristics of the reservoir, development policies, development conditions and environment. Because many factors, such as conditions, are involved, it is important to optimize the transition of production methods at different stages according to the state of the reservoir. So far, there has been only one investment and effort in the three mechanical production methods: the pump set, the electric pump and the screw pump. Consumption analysis is easy to evaluate. Daqing No.2 Oil Production Plant has conducted a special study on "How to evaluate machinery", but only from the aspects of one-time investment, energy consumption and displacement range, adaptability, screw pump manufacturers, pump range, etc. We will compare and discuss petroleum engines. The analysis from economic theory is not systematic and comprehensive. No other domestic field data show the economic limitations of using modern economic analysis methods to analyze theoretical oil recovery techniques and the economics of traditional lifting methods. Benefit comparison. When establishing the evaluation database and developing the software of product economic limit, it is impossible to find the established database model and software because of the immaturity of the theoretical model.

In order to take advantage of new production technologies, a comprehensive evaluation of the suitability of the upgrading process, cost reduction and subsequent investment was conducted. It is necessary to determine the reasonable economic range suitable for reducing the production technology of single screw pump manufacturers. It is very important to meet the development needs of lifting technology. Therefore, the study of economic profit rate analysis technology is very important to improve the economic adaptability of oil field lifting technology, and has broad application prospects.